Product Description:

WC-10CO-4CR 10-2um

WC-10CO-4CR is a hard alloy material composed of tungsten carbide

(WC), cobalt (Co), and chromium (Cr), with a particle size of 10-2

micrometers (um).

This material is widely used in various industrial applications due

to its excellent mechanical properties and wear resistance.

The numerical representation of WC-10CO-4CR indicates the

percentage composition of each component in the material.

Specifically, tungsten carbide (WC) accounts for 10% of the total

mass, cobalt (Co) accounts for 4%, and chromium (Cr) makes up the

remaining proportion, typically 86%.

One of the distinctive features of WC-10CO-4CR is its tiny particle

size, which usually ranges from 10 to 2 micrometers (um). This

characteristic contributes to its high hardness and strength.

Furthermore, the combination of tungsten carbide, cobalt, and

chromium creates a material that is highly resistant to wear and

corrosion, making it a popular choice for cutting tools,

wear-resistant overlays, and other industrial components.

Features:

Characteristics of WC-10CO-4CR

WC-10CO-4CR stands out for its exceptional properties, some of

which are highlighted below:

High Hardness

With its high hardness, WC provides WC-10CO-4CR with exceptional

wear resistance and durability.

High Strength

The cobalt (Co) component in WC-10CO-4CR contributes to its

impressive strength and toughness, making it capable of

withstanding high levels of stress and impact loads.

Corrosion Resistance

Thanks to the addition of chromium (Cr), WC-10CO-4CR exhibits

improved corrosion resistance, allowing it to function effectively

in even the harshest environments, resisting corrosion and

oxidation.

Thermal Stability

WC-10CO-4CR maintains excellent stability when exposed to high

temperatures, making it well-suited for use in high-temperature

applications.

Technical Parameters:

| Technical Parameter | Value |

|---|

| Chemistry | 86WC,10Co,4Cr |

| Classification | Carbide, Tungsten-based |

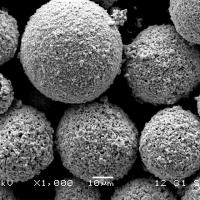

| Morphology | Spheroidal |

| Operating Temperature | Max Operating Temperature 750℃ |

| Manufacture | Agglomerated And Sintered |

| Process | HVOF, HVAF |

| Corrosive wear resistance | Corrosive Wear Resistance |

| Coating Materials | WC-CO-CR |

| HVAF Coating Materials | HVAF WC-CO-CR |

| HVAF Powder | HVAF WC-CO-CR Powder |

Applications:

WC-10CO-4CR Application

WC-10CO-4CR, also known as tungsten carbide-cobalt-chromium, has a

diverse range of uses in various industries. Its exceptional

properties make it a popular choice in cutting tools, drill bits,

abrasives, molds, and mechanical components.

One of the major applications of WC-10CO-4CR is in the

manufacturing of cutting tools. Its high hardness and wear

resistance make it ideal for producing tools that can withstand

heavy use and maintain their sharpness for longer periods. This

makes WC-10CO-4CR a valuable material in industries such as

metalworking and woodworking, where precision and durability are

crucial.

In addition to cutting tools, WC-10CO-4CR is also widely used in

the production of drill bits. Its hardness and toughness make it

suitable for drilling through various materials, including metal,

wood, and concrete. This results in efficient and effective

drilling operations, making WC-10CO-4CR an essential component in

the construction, mining, and oil and gas industries.

Abrasives, such as sandpaper and grinding wheels, also benefit from

the superior properties of WC-10CO-4CR. The high hardness of this

material enables it to withstand the intense friction and pressure

involved in grinding and polishing, resulting in more durable and

efficient abrasive products.

Molds used in injection molding processes also often incorporate

WC-10CO-4CR. This is due to its excellent wear resistance, which

helps to prolong the lifespan of the molds and reduce the need for

frequent replacements. As a result, manufacturers can save on

production costs and increase their productivity.

Finally, mechanical components, such as bearings and seals,

commonly utilize WC-10CO-4CR. Its hardness, strength, and corrosion

resistance make it suitable for use in heavy-duty and high-speed

applications, where wear and tear are a concern. By incorporating

WC-10CO-4CR into these components, manufacturers can ensure their

durability and reliability in various operating conditions.

Customization:

Thermal Spray Powders - BODA Customization Service

Brand Name: BODA

Model Number: Fine Size WC-10Co-4Cr

Place of Origin: China

Certification: ISO9001:2015

Minimum Order Quantity: 50kgs

Price: $60-65/kgs

Packaging Details: 50kgs/Drum

Delivery Time: 7-10days

Payment Terms: Negotiation

Supply Ability: 10tons/Month

Chemistry: 86WC,10Co,4Cr

Morphology: Spheroidal

Manufacture: Agglomerated And Sintered

Corrosive wear resistance: Corrosive Wear Resistance

Operating Temperature: Max Operating Temperature 750℃

BODA offers customized services for our Thermal Spray Powder

WC-10Co-4Cr, also known as Coating Materials WC-CO-CR or

WC-10Co-4Cr Powder. Our high quality product is manufactured in

China and certified with ISO9001:2015. The minimum order quantity

is 50kgs and the price ranges from $60 to $65 per kilogram.

We package our product in 50kgs drums and deliver within 7-10 days.

Payment terms are negotiable and we have a supply ability of 10

tons per month. Our Thermal Spray Powder WC-10Co-4Cr has a

chemistry composition of 86WC, 10Co, 4Cr and a spheroidal

morphology. It is produced through agglomeration and sintering

techniques, ensuring its high quality and performance.

Our Thermal Spray Powder WC-10Co-4Cr is known for its excellent

corrosive wear resistance and can withstand operating temperatures

of up to 750℃. With our BODA Customization Service, we can tailor

our product to meet your specific needs and requirements. Contact

us now to learn more about our customized services for Thermal

Spray Powders.

Packing and Shipping:

Thermal Spray Powders - Packaging and Shipping

At Thermal Spray Powders, we take great care in ensuring that our

products reach our customers in perfect condition. Our packaging

and shipping procedures are designed to protect the integrity of

our thermal spray powders and to guarantee their safe delivery to

your doorstep.

Packaging

All of our thermal spray powders are packaged in sturdy, airtight

containers to prevent any contamination or moisture from affecting

the quality of the product. The containers are labeled with the

product name, lot number, and expiration date for easy

identification and traceability. We also offer custom packaging

options for bulk orders.

Shipping

We ship our thermal spray powders worldwide using reliable and

efficient shipping carriers. Our team carefully packs each order to

ensure that the powders are protected during transit. We also offer

expedited shipping options for urgent orders.

For international orders, we provide all necessary documentation

and comply with customs regulations to ensure a smooth and

hassle-free delivery process. We also offer tracking services for

all orders, so you can monitor the progress of your shipment.

Upon delivery, please inspect the packaging for any damage. If you

find any issues, please contact us immediately and we will work to

resolve the problem as quickly as possible.

Thank you for choosing Thermal Spray Powders. We are committed to

providing you with the best quality products and services. If you

have any further questions or concerns about our packaging and

shipping, please do not hesitate to contact us.