Product Description:

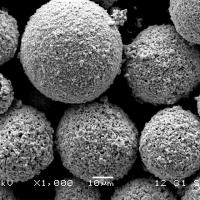

Agglomerated And Sintered Thermal Spray Powders WC-10Co-4Cr 10-2um

WC-10CO-4CR 10-2um : A Durable Alloy Material for Industrial

Applications

WC-10CO-4CR is a hard and durable alloy material that is widely

used in industrial applications. It is composed of three elements:

tungsten carbide, cobalt, and chromium, with the numerical

representation indicating the percentage composition of each

component. In this case, tungsten carbide accounts for 10% of the

total mass, cobalt accounts for 4%, and chromium makes up the

remaining proportion, typically 86%. In addition, this material has

a small particle size of 10-2 micrometers (um), contributing to its

excellent mechanical properties and wear resistance.

Known for its high strength and durability, WC-10CO-4CR is a

popular choice for various industrial applications. Its excellent

mechanical properties make it suitable for use in metal cutting

tools, mining equipment, and wear-resistant parts for machinery.

The combination of tungsten carbide, cobalt, and chromium results

in a unique alloy material that can withstand high temperatures and

extreme conditions.

One of the key factors contributing to the exceptional wear

resistance of WC-10CO-4CR is its small particle size. This enables

longer tool life, making it a cost-effective choice for industrial

processes. In addition, the use of this alloy material can lead to

increased efficiency and productivity in various industrial

operations.

Features:

Features of WC-10CO-4CR 10-2um

The material WC-10CO-4CR possesses the following characteristics:

- High Hardness: WC has a high level of hardness, giving WC-10CO-4CR exceptional

wear resistance and long-lasting durability.

- High Strength: The inclusion of cobalt (Co) in WC-10CO-4CR contributes to its

strength and toughness, allowing it to withstand high levels of

stress and impacts.

- Corrosion Resistance: The addition of chromium (Cr) improves the corrosion resistance of

WC-10CO-4CR, making it suitable for use in harsh environments that

involve exposure to corrosion and oxidation.

- Thermal Stability: Even under high temperatures, WC-10CO-4CR maintains good

stability, making it an ideal choice for applications that operate

in high-temperature conditions.

Technical Parameters:

| Attribute | Value |

|---|

| Morphology | Spheroidal |

| Classification | Carbide, Tungsten-based |

| Process | HVOF, HVAF |

| Chemistry | 86WC,10Co,4Cr |

| Manufacture | Agglomerated And Sintered |

| Operating Temperature | Max Operating Temperature 750℃ |

| Corrosive wear resistance | Corrosive Wear Resistance |

| WC-CO-CR | 86WC,10Co,4Cr |

| WC-CO-CR | 86WC,10Co,4Cr |

| WC-CO-CR | 86WC,10Co,4Cr |

Applications:

The WC-10CO-4CR 10-2um alloy has a broad range of uses across various industries,

including cutting tools, drill bits, abrasives, molds, and

mechanical components. Its properties make it ideal for creating

tools and parts that require exceptional hardness and resistance to

wear, improving their durability and overall performance.

Customization:

BODA Thermal Spray Powders Customization Service

Brand Name: BODA

Model Number: Fine Size WC-10Co-4Cr 10-2um

Place of Origin: China

Certification: ISO9001:2015

Minimum Order Quantity: 50kgs

Price: $60-65/kgs

Packaging Details: 50kgs/Drum

Delivery Time: 7-10days

Payment Terms: Negotiation

Supply Ability: 10tons/Month

Morphology: Spheroidal

Operating Temperature: Max Operating Temperature 750℃

Classification: Carbide, Tungsten-based

Manufacture: Agglomerated And Sintered

Process: HVOF, HVAF

Key Words: WC-CO-CR, HVOF WC-10Co-4Cr, HVAF WC-CO-CR, BODA Thermal

Spray Powders

Packing and Shipping:

Product Name:

Thermal Spray Powders

Packaging and Shipping:

- The Thermal Spray Powders are packaged in sealed,

moisture-resistant bags to ensure product quality and integrity

during shipping.

- The bags are then placed in sturdy cardboard boxes for added

protection during transit.

- Each box is clearly labeled with the product name, lot number, and

expiration date for easy identification.

- All packaging materials used are eco-friendly and recyclable.

- The boxes are then loaded onto pallets and securely wrapped for

safe transport.

- For international shipments, the necessary customs documents and

declarations will be included with the shipment.

- Shipping options include air, sea, or land transport depending on

the customer's location and preference.

- We work with trusted and reliable shipping partners to ensure

timely delivery and minimize any potential damage during transit.