Product Description:

Spherical Cast Tungsten Carbide Powder For Oil And Gas Industry

Spherical Cast Tungsten Carbide

| Grade | W | T.C | F.C | Fe | Ti | Mo+Co+Ni | Cr | Vi | Si |

| BD20401 | 95-96 | 3.8-4.2 | ≤0.08 |

≤0.5 | ≤0.1 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.02 |

| Micro-hardness HV 0.1 | Apparent Density g/cm3 | Melting Point ℃ |

| >2500 | >9.0 | 2525 |

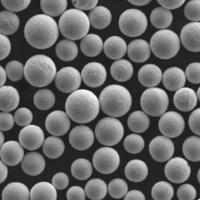

Spherical Cast Tungsten Carbide,With cast tungsten carbide as raw

materials, adopted high temperature modification, spheroidizing

method by plasma technology, make it on the basis of the original

cast tungsten carbide chemical performance is stable, has many

characteristics, such as uniform structure and good liquidity.

The products is spherical- dark gray powder,It’s mainly used for

reinforcement of wear-resistant of subject surface, making PDC,PDC

drill tools,as well as spray welding etc.

Features:

Spherical cast tungsten carbide offers exceptional hardness that ranks among the hardest materials available on the market.

As a result, it has incredible wear resistance properties, enabling

it to withstand abrasive wear and impact.

This makes it suitable for various demanding applications.

The shape of the particles also gives it superior properties.

Its spherical shape allows for excellent flowability, providing

uniform distribution and consistent coverage when used as a coating

or incorporated into composite materials.

Overall, spherical cast tungsten carbide is the ideal choice for

those seeking a material that exhibits unprecedented hardness while

also having superior wear resistance properties.

Technical Parameters:

Benefits:

Spherical cast tungsten carbide offers the following advantages:

- Extended Service Life: Spherical cast tungsten carbide offers exceptional wear

resistance. This results in extended service life for components

and surfaces, reducing downtime, maintenance costs, and the need

for frequent replacements.

- Enhanced Performance: The hardness and wear resistance of spherical cast tungsten

carbide lead to improved performance in wear-intensive

applications, providing reliable operation and increased

productivity while reducing material loss.

- Versatility: The spherical shape of the particles allows for flexible

application across different industries and applications and makes

it possible to incorporate it into various processes, such as

coating deposition, welding, and additive manufacturing.

- Cost Savings: Spherical cast tungsten carbide is capable of providing extended

service life and minimizing downtime, which can result in

significant cost savings for industries relying on wear-resistant

solutions.

Applications:

Spherical cast tungsten carbide has numerous practical

applications. It is widely used in wear protection, hardfacing and

welding, additive manufacturing, and composite materials.

In wear protection, the tungsten carbide is often applied to

surfaces exposed to abrasive wear, such as mining equipment, oil

and gas tools, and industrial machinery components.

When it comes to hardfacing and welding, the tungsten carbide

particles can be incorporated to enhance the wear resistance and

extend service life, especially in applications with severe wear

and impact.

The spherical cast tungsten carbide is also employed in additive

manufacturing processes, such as powder bed fusion, which enables

the fabrication of precise and wear-resistant components. It also

finds application in composite material production, as it can be

mixed with other materials like polymers and metals, creating

composites with improved wear resistance. These composites are

utilized in many industries from aerospace and automotive to

tooling.

Customization:

Custom Spherical Cast Tungsten Carbide

- Brand Name: BODA

- Model Number: Spherical Cast Tungsten Carbide

- Place of Origin: China

- Certification: ISO9001:2015

- Minimum Order Quantity: 50kgs

- Price: $55-$60.0/kg

- Packaging Details: 50kgs/Drum

- Delivery Time: 7-10days

- Payment Terms: Negotiation

- Supply Ability: 10tons/Month

- Material: Tungsten Carbide

- Manufacture: Fused, Crushed And Plasma Densified

- Product Name: Spherical Cast Tungsten Carbide

- Shape: Spherical

- Apparent Density: 9.0 – 11.0 G/cm3

Packing and Shipping:

Spherical Cast Tungsten Carbide Packaging and Shipping:

The spherical cast tungsten carbide powders are packaged in steel

drum with an inner plastic bag to protect the powder from moisture

and dust.

The drums are then placed in shipping containers for protection

against any external damage.

All shipments are carefully tracked and monitored to ensure that

the components arrive without damage.