Zhuzhou Jiangwu Boda Hard-facing Materials Co., Ltd. was founded in

2007, it’s located in Jiulong Technical and Economic Development

Zone, Yanling,Hunan Province.It’s established by "Jiangxi Tungsten

Industry Co., Ltd." and "Zhuzhou Boda Tungsten industry Co., Ltd."

as a joint venture.

Jiangxi Tungsten Industry Co., Ltd belongs to Jiangxi Tungsten

Holding Group Company Limited(JXTC) which is a centry-old

provincial state-owned large enterprise, and executive director

unit of China Nonferrous Metals Industry Association . JXTC Group

has 117 member enterprises, with 5 national research and innovation

platforms which refers to national enterprise technology center and

Post-Doctoral Research Center etc.It’s mainly engaged in tungsten,

tantalum niobium, rare earth, cobalt nickel and other rare metal of

mining, smelting, processing, trade, as well as machinery

manufacturing, recycled metals, scientific research and development

business, is an important manufacturers & trader of whole tungsten

industry products chain at domestic and overseas

Zhuzhou Jiangwu Boda Hard-facing Materials Co., Ltd. is a

self-export-oriented production and marketing enterprise, It’s has

been committed to hard-surface materials manufacturing and sales

since 1993, Which also has a broad and stable market at home and

abroad.

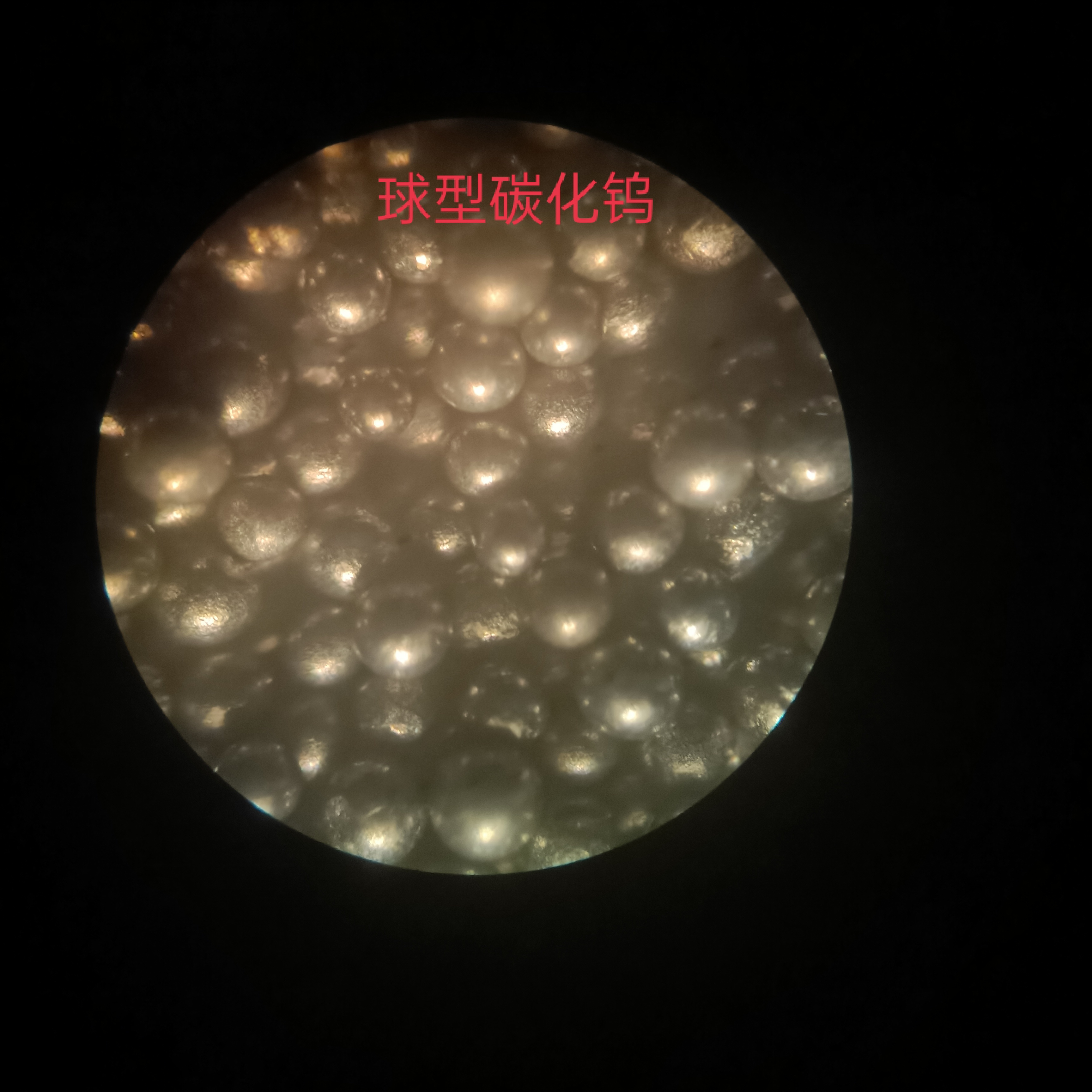

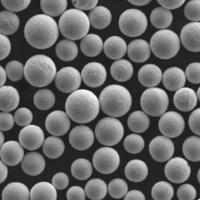

Zhuzhou Jiangwu Boda Hard-facing Materials Co., Ltd. sets thermal

spraying powder, hard-facing materials, refractory metal carbide

and other new materials products R & D, production and sales in

one, with professional R & D, production, sales and management team

and quality assurance system ISO9001:2015 , Our products’ quality

is stable, sold at home and abroad and widely used in oil

extraction, aerospace, mining mining, mechanical tools and other

fields.

"Boda" brand has won the trust and praise of many customers

worldwide with its "excellent quality, brand complete, thoughtful

service" image,

"Jiangwu boda" will continue to uphold the "customer first,

integrity-based, win-win cooperation" concept, work together with

friends from all walks of life at home and abroad to create a

better future!